Stories > From Corn to Bioplastic

From Corn to Bioplastic

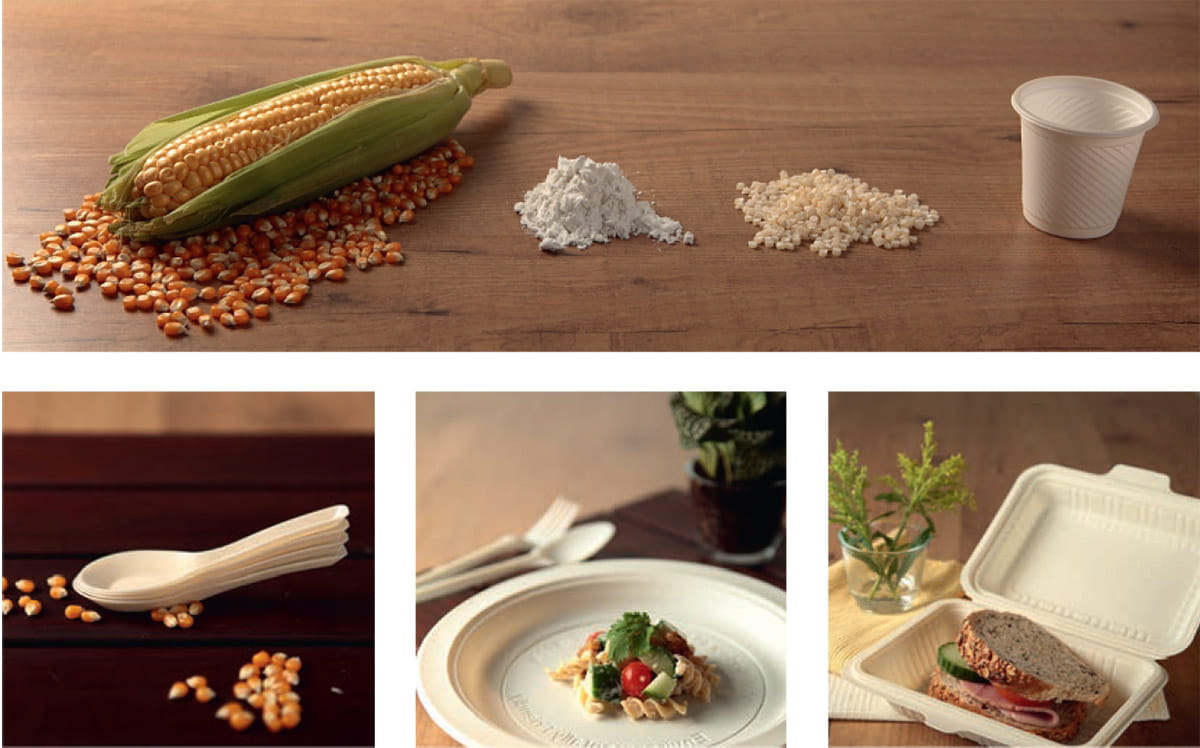

Olive Greenʼs products are made by combining cornstarch and plastic; its product range includes disposable food containers, as well as disposable plates and cutlery.

Homegrown company Olive Green makes disposable tableware, carrier bags and other packaging products from corn as an eco-friendly alternative to petroleum-based plastic products.

BY SASHA GONZALES

PHOTOS OLIVE GREEN

he production of petroleum-based plastic products not only depletes the world’s fossil fuel reserves, it also contributes to global warming by emitting carbon dioxide.

In addition, some petroleum-based plastic products can take up to 500 years to break down in landfills, and incinerating them only releases more carbon dioxide into the atmosphere. To address the issue of plastic waste and help reduce carbon emissions, a Singapore company called Olive Green has come up with an alternative to petroleumbased plastic packaging.

Founded in 2008, Olive Green develops, manufactures and distributes bioplastic Origo - made primarily from cornstarch – in the form of disposable tableware, carrier bags and other packaging products. A family friend had introduced Aloysius Cheong, Olive Green’s managing director and chief executive officer, to a company that was producing bioplastic in China in 2006.

“ Our CornWare is widely used in the food and beverage industry, and is registered in more than 30 countries, including the United States. The products are practical, sturdy, customisable and affordable. ”

Aloysius Cheong, managing director and chief executive officer of Olive Green

At the time, Cheong, who was managing a tuition agency, was looking for eco-friendly alternatives to petroleum-based plastic products. He sensed an immense potential for green materials in the disposable packaging industry as consumers were becoming more environment-conscious. He decided to create cornstarch-based eco-friendly products at competitive prices for the market. He says: “From food and beverage packaging to the electronics and pharmaceutical industries, the sectors we could enter into were limitless. We just had to get the product and price right to make it work.”

MULTIPLE ADVANTAGES

Origo is environmentally friendly and sustainable in a number of ways. It significantly reduces our dependency on petroleum, and produces far less carbon dioxide than petroleum-based plastic when it is landfilled or incinerated. The corn used is a fast-growing crop grown specifically in China for this purpose, so it does not contribute to global food shortage.

To make Origo, Olive Green chemically combines cornstarch with a plastic hybrid – in a ratio of just over 60 per cent cornstarch to slightly less than 30 per cent plastic – and a small amount of filler ingredients. It then uses specialised machinery to create different products, such as its CornWare brand, which includes bento boxes, plates, cups and cutlery. It also makes trash bags and carrier bags under the CornBag brand.

Cheong says that plastic is added into the production to make its products functional. He adds that while a plate made of 100 per cent cornstarch is more eco-friendly, it is not functional as it will be too soft and cannot hold liquids properly. Plastic additives make the plate firmer, more suitable for its intended purpose, and more affordable to produce.

As it is composed mainly of cornstarch, a natural raw material, Origo is 100 per cent biodegradable and 70 per cent compostable. Cheong says it can be broken down naturally by microbes at a composting facility. The corn component is turned into humus, an organic material, while the plastic portion is broken down into nano-sized particles. The compost formed is non-toxic, so it does not pollute the land or water bodies when it runs off and finds its way into rivers and seas.

Unlike tableware made from conventional plastic or styrofoam, its tableware can be heated to a high temperature, such as in a microwave oven, without releasing harmful substances into the food. Says Cheong: “Our CornWare is widely used in the food and beverage industry, and is registered in more than 30 countries, including the United States. The products are practical, sturdy, customisable and affordable.”

Apart from selling its products in Singapore’s supermarkets and exporting them overseas to countries like the United Kingdom and the United States, Olive Green also supplies them to companies such as food services and facilities management company Sodexo in Singapore. Roshith Rajan, Sodexo’s corporate responsibility lead for Asia-Pacific, says: “Consumers are increasingly aware of the challenges faced by the environment and count on Sodexo to provide responsible services. Our collaboration with Olive Green in the use of biodegradable CornWare products is a step in this direction.”

Moving ahead, Cheong says that his focus for the next three years is to work on introducing better products to the market.