Stories > Rising to the Challenge

Rising to the Challenge

Singapore-bred innovations are making significant contributions to help combat the Covid-19 pandemic the world over.

BY ALYWIN CHEW

ecessity is the mother of invention. When faced with a predicament – not least one that threatens the existence of mankind – humans instinctively embark on a journey of self-preservation. It results in innovations that would not have been invented under normal circumstances.

Singapore has joined the ranks of nations around the world that are tirelessly working to contain the ongoing Covid-19 pandemic. To this end, the city state has demonstrated its proficiency in leveraging technology to swiftly tackle health emergency challenges.

During the SARS epidemic back in 2003, the Infrared Fever Screening System was developed by Singapore’s Defence Science and Technology Agency – an organisation affiliated to the Ministry of Defence – in response to the need to perform mass temperature screenings.

“The total critical mass of Singaporean biomedical R&D is less than 1 per cent of the [world’s], and yet we are the international leader in this area for Covid-19.” Professor Wang Linfa, Duke-NUS

Repurposed from the existing military thermal imager, the device was the first of its kind in the world, and relied on a two-point detection concept instead of the conventional measurement of skin temperature to screen for fever. Such was its effectiveness that dozens of units could be found at medical institutions, transportation hubs and public spaces across Asia shortly after its release.

With fever also a symptom of Covid-19, temperature screening has again become an indispensable mechanism. This time round, Singapore enterprises KroniKare and Integrated Health Information Systems have risen to the challenge with the development of the iThermo – a smartphone equipped with thermal and 3D laser cameras that is able to screen individuals and provide real-time updates about the number of febrile people identified.

Powered by artificial intelligence, it offers a more affordable and portable alternative to the bulky screening machines currently used, and is deployed at hospitals, places of worship, ports, schools and offices.

MONITORING AND TESTING

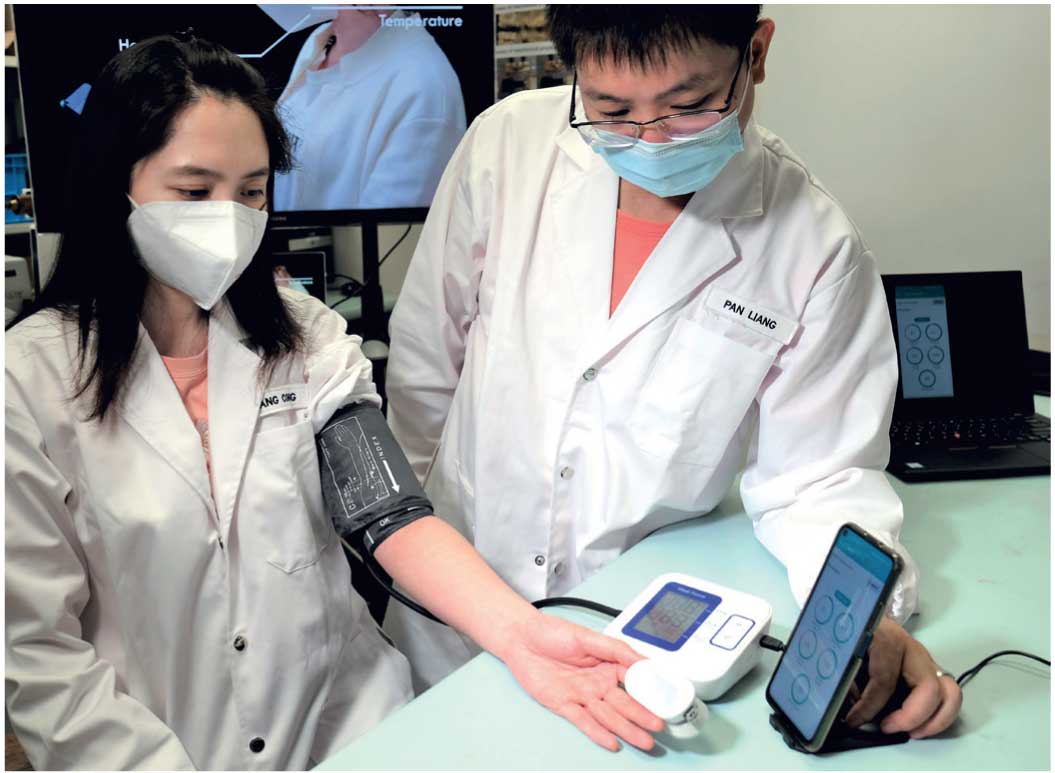

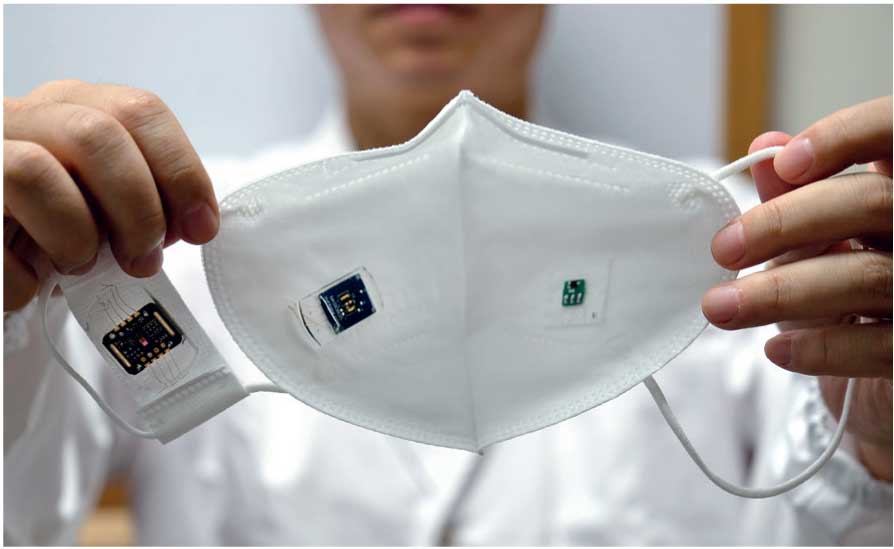

Another new device that has emerged during the Covid-19 pandemic is a smart mask jointly developed by scientists and researchers from the Agency for Science, Technology and Research (A*STAR) – which specialises in biomedical, physical and engineering sciences research – and Nanyang Technological University (NTU).

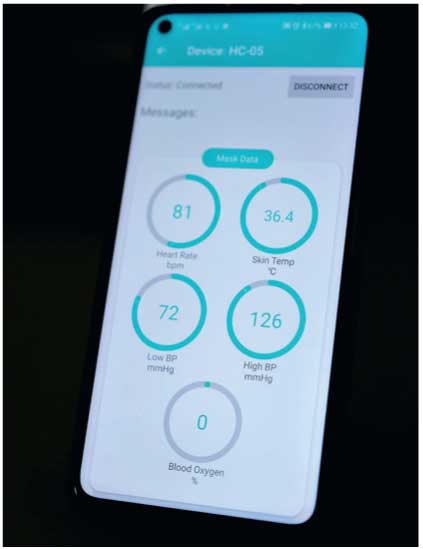

Through the use of sensors, which are embedded in a water-resistant polymer material that is attached to the inside of the mask, this item allows frontline medical workers to monitor a patient’s vital signs remotely instead of manually performing the task – thus greatly reducing the risk of infection. It has also helped enhance efficiency: Nurses no longer have to move bulky equipment between isolation wards.

Apart from the fact that it can be washed and reused multiple times, the mask is also equipped with a Bluetooth device that allows users to monitor their own vital signs on a smartphone. At the prototype stage, each mask costs about S$50 to manufacture, although the research team estimates that it should come down to S$20 when put to mass production.

“Besides application in medical settings, there is potential for the mask to be used at nursing homes or hostels. The remote monitoring of residents’ conditions will allow their health to be observed continuously at a central station,” says Professor Loh Xian Jun, executive director, Institute of Materials Research and Engineering at A*STAR. Prof Loh adds that the mask has already attracted the attention of several parties, though deals have yet to be finalised.

Scientists from the Institute of Materials Research and Engineering at Singapore’s A*STAR research agency and Nanyang Technological University have jointly developed a Bluetooth-enabled reusable mask that can monitor a patient’s vital signs during Covid-19 treatment. The mask comes with sensors embedded into its waterresistant polymer material.

An alternative innovation that medical professionals can use for remote monitoring of patients’ vitals is the new Biovitals Sentinel solution by Singapore-based firm Biofourmis. Unlike the smart mask, this new solution involves having patients wear a clinical-grade biosensor on their upper arms. The sensor can perform measurements of more than 20 physiological signals, including temperature, heart rate, respiration rate and blood oxygenation.

What’s unique about this innovation, says Biofourmis CEO and founder Kuldeep Singh Rajput, is that the sensor can, through the use of AI-based analytics, predict if a patient’s condition will worsen up to 21 hours in advance. This, in turn, allows doctors to perform crucial interventions.

In late July 2020, Biofourmis announced that its Biovitals Sentinel platform had been deployed by Singapore’s Ministry of Health to monitor Covid-19 patients. Additionally, the state-of-the-art sensors have also been used at medical facilities in Hong Kong, Australia, the US and the UK.

Local entities have also made headway in terms of testing capabilities. A test kit called cPass, which is capable of detecting the antibodies that neutralise the coronavirus in both humans and animals, has become the world’s first commercial kit to receive authorisation from the United States Food and Drug Administration (FDA).

Invented by Singaporean researchers from the Duke-National University of Singapore (NUS) Medical School, cPass can be used to determine a number of markers that will help biotech researchers strengthen their key coronavirus findings, such as analysing the efficacy of vaccines, determining the percentage of the population that has already been infected, and assisting in contact tracing. Its most significant advantage is that it does not require highly specialised equipment or training, while making results available in just an hour.

Given how rigorous the FDA approval process is, the recognition of cPass represents a major achievement for Singapore’s biotech and research sectors. “The total critical mass of Singaporean biomedical R&D is less than 1 per cent of the [world’s], and yet we are the international leader in this area for Covid-19,” said prof Wang Linfa, director of the emerging infectious diseases programme at Duke-NUS, in an interview with local broadsheet The Straits Times.

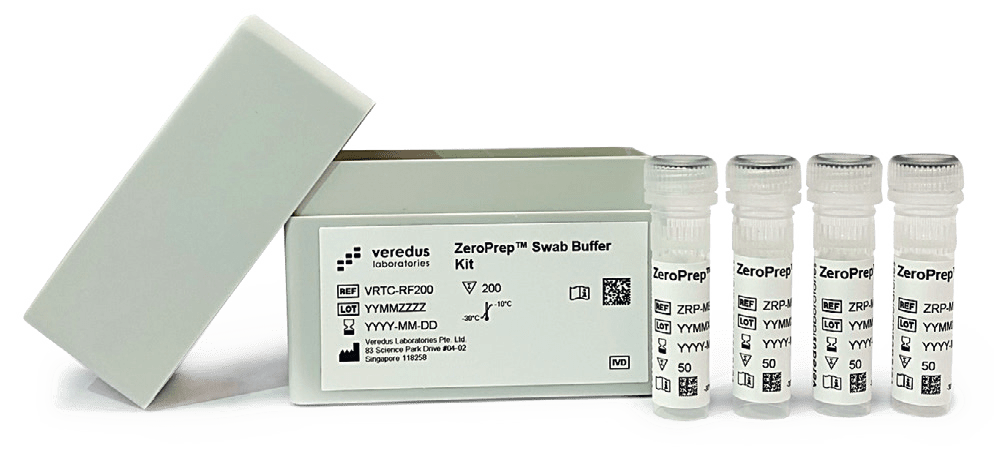

Veredus Laboratories, a Singapore biosciences research and diagnostic firm, has launched two new test kits that use nasal swab and saliva samples for Covid-19 testing.

“WE HAD 14 EMPLOYEES ON THREE CONTINENTS WORKING ROUND THE CLOCK TO DEVELOP THE APP. WE KNEW HOW URGENT IT WAS AND WE KNEW THAT WE COULD HELP MAKE A DIFFERENCE BY DEDICATING OUR EXPERTISE AND TIME.”

Yet another example of global research work with far-reaching impact is that of homegrown medical device company Veredus Laboratories. It made the headlines recently after launching two new test kits for Covid-19 that increase the efficiency of the testing process. One kit uses nasal swab samples; the other relies on a far less invasive approach: saliva samples.

Conventional Covid-19 tests, says Veredus CEO Rosemary Tan, are processed in the lab through a technique called the polymerase chain reaction, and determining the result of a sample can take up to two hours. The new kits reduce the time required by about 30 minutes. These new kits have already been acquired by customers from Singapore, Indonesia, Japan and the Philippines. Previously, the company had launched the world’s first lab-on-chip detection kit that can identify more than 10 influenza subtypes. Called VereFlu, the kit doesn’t require lab processing, and can produce results within two hours.

NEED FOR SPEED

Equally impressive is the time taken for scientists to produce the various innovations. According to Professor Chen Xiaodong from NTU’s School of Materials Science & Engineering, it took only a month to produce the first iteration of the smart mask.

“Prof Chen and I have worked together on this research for over five years. That is how we managed to quickly apply what we have learnt into the making of this mask,” says Prof Loh, who points out that it usually takes around six months to develop such a device. “This shows the importance of collaborations across the research ecosystem.”

For Biofourmis, the Biovitals Sentinel took just three weeks to bring to fruition. This was made possible only by the tireless effort of the company’s employees, who worked round the clock starting from mid-February, when Rajput received a call from professors and clinicians from the University of Hong Kong, who inquired if the company’s existing technology could be adapted to deal with Covid-19.

“We had 14 employees on three continents working round the clock to develop the app. We knew how urgent it was as the pandemic continued to spread both in Hong Kong and globally, and we knew that we could help make a difference by dedicating our expertise, time and knowledge,” he says.

The labs at Veredus were similarly a hive of activity regardless of the time of day, with researchers driven not by the desire to grab the headlines but a sense of urgency.

“To us, this is not just about developing something innovative – it’s also about bringing a much needed, much desired solution to the people,” says Tan.

“This pandemic is evolving rapidly, so one of the challenges to the research process would be to anticipate the next development that would make an impact to the testing, and how quickly we can carry out the research and develop it.”