Stories > Treasure, Not Trash

Treasure, Not Trash

Singapore clean-technology company BlueRen helps address the environmental issues associated with plastic waste – by turning it into a valuable resource used to strengthen materials like concrete.

ILLUSTRATIONS 123RF

ne man’s trash is certainly another man’s treasure for Singapore-based start-up BlueRen, which has found an environmentally friendly way to convert plastic waste into carbon nanotubes (CNTs).

A CNT is a tiny cylinder made of carbon molecules and about 10,000 times finer than a strand of human hair. Yet it can be at least 100 times stronger than steel of the same diameter and only one-sixth as heavy. It also conducts electricity and heat better than copper. Adding CNTs in small quantities to the production of concrete, floorboards of shipping containers and plastics can enhance the strength of the materials.

BlueRen’s founders, Dr Wong Chui Ling, a researcher at the Nanyang Technological University (NTU), and Aravind Muthiah, a PhD candidate at NTU, met at an NTU research lab in 2013. Sharing a vision of using technology for social good, the two had hit on the idea of converting plastic waste into CNTs after finding out that more than 90 per cent of plastic in Singapore goes unrecycled.

They founded BlueRen, which means “blue lotus” (“ren” is Japanese for lotus), last October. Blue represents water, which is essential for human life, while lotus is symbolic of the founders’ wish for the team to rise above adversity, just as the lotus flower is known to blossom in muddy water.

Says Dr Wong: “Current waste-processing technologies are all about manufacturing products that are further down the value chain. Our idea of upcycling, which involves the creation of products that are of higher value, seeks to correct this mindset by showing manufacturers that waste is indeed valuable.”

FROM WASTE TO RESOURCE

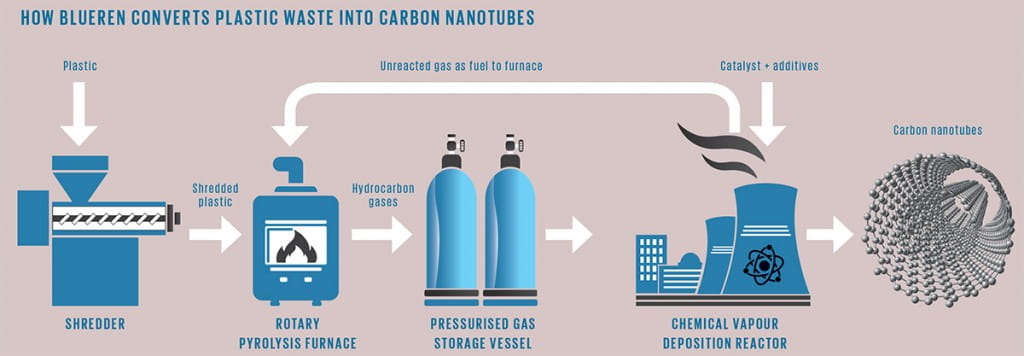

BlueRen’s technology involves a two-step process. The first step, known as pyrolysis, involves heating up plastic waste in the absence of air and converting it into a gaseous form. These gases are called hydrocarbons and are a valuable fuel source. The second step involves passing the hydrocarbon gases over an iron-based catalyst, in a process known as chemical vapour deposition, to produce carbon nano-additives or CNTs.

The process does not have a zero carbon footprint, as not all of the hydrocarbon gases become CNT. The unused gas can be converted into oil or used as a fuel, but results in carbon dioxide being released. This is a challenge that BlueRen is working to overcome to achieve carbon neutrality.

Its founders say that as of January this year, BlueRen has been the only company in the world to produce CNTs from plastic. However, there are other companies that use rubber as a raw material in a similar process to make CNTs.

BlueRen’s founders also see potential in the application of its technology, which enhances the yield of nano-additives from hydrocarbon gases. Says Muthiah: “The process has been well studied in laboratories in many parts of the world. But BlueRen’s technology has demonstrated that key additions in the second stage of the process can enhance the yield and quality of the CNTs.”

“We all have a responsibility to protect the environment, and what better way to do so than through the upcycling of waste.”

BlueRen co-founder, Dr Wong Chui Ling

Using the same technology, BlueRen could also process other waste products such as rubber or biomass. The technology could similarly be used to process biogas and produce other types of nano-additives.

Still, it is early days before BlueRen’s technology is fully commercialised. It is now focused on using its CNTs in concrete and is collaborating with concrete manufacturer Samwoh Corporation to design a pre-pilot plant, which will provide an adequate quantity of CNTs for testing.

Last October, it was one of 11 groups from a field of about 300 applicants that won the DBS Foundation Social Enterprise Grant. The grant enables social enterprises to test and create prototypes, improve existing processes or scale up their existing business to achieve greater social impact. BlueRen is using this grant to build the pre-pilot plant.

In the meantime, it will continue to improve on its technology so that it can be scaled up for commercialisation. It is also looking for potential partners to commercialise the technology in Singapore. Say its founders: “After that, we will continue to expand the possible product ranges into additives for rubber, for example.”