Stories > Farming In The Sky

Farming In The Sky

Sky Greensʼ workers preparing the produce for delivery to the supermarkets.

Singapore-based Sky Greens is one of the world’s first hydraulic-driven vertical farms, which provide an environmentally friendly and innovative solution for feeding an urban population within a small land area.

ILLUSTRATION RODRIGO FORTES

ith a total land area of 718.3 sq km, Singapore faces space constraints that make it especially challenging for land-intensive agricultural companies to thrive. In fact, over 90 per cent of food consumed in Singapore is imported.

But that has not stopped home-grown urban agriculture solution company, Sky Urban Solutions Holdings, from building Sky Greens, one of the world’s first low carbon, commercialised vertical farms, which aims to meet the challenge of local food production within a limited land area.

The company, founded in 2011, is even exporting its food-growing technology. Its first overseas farm was set up in Hainan, China, and it has an ongoing pilot project in Bangkok, Thailand. It is also exploring other projects in China, Malaysia, Saudi Arabia and the United States.

Sky Urban Solutions Holdings has won several awards for its technology, including the top honour of the Green Technology Award during last year’s Singapore Sustainability Awards, which recognises organisations with outstanding sustainable business practices and innovative green technology solutions.

The story of Sky Greens began in 2009 when its founder and chief executive officer Jack Ng used his expertise from more than 30 years in the building and construction industry, to build a prototype structure for vegetable cultivation.

He came up with the idea during the financial crunch in 2009 after he saw how food prices went up because of supply disruptions overseas. The solution, he thought, was to grow more food locally.

GREEN TECHNOLOGY

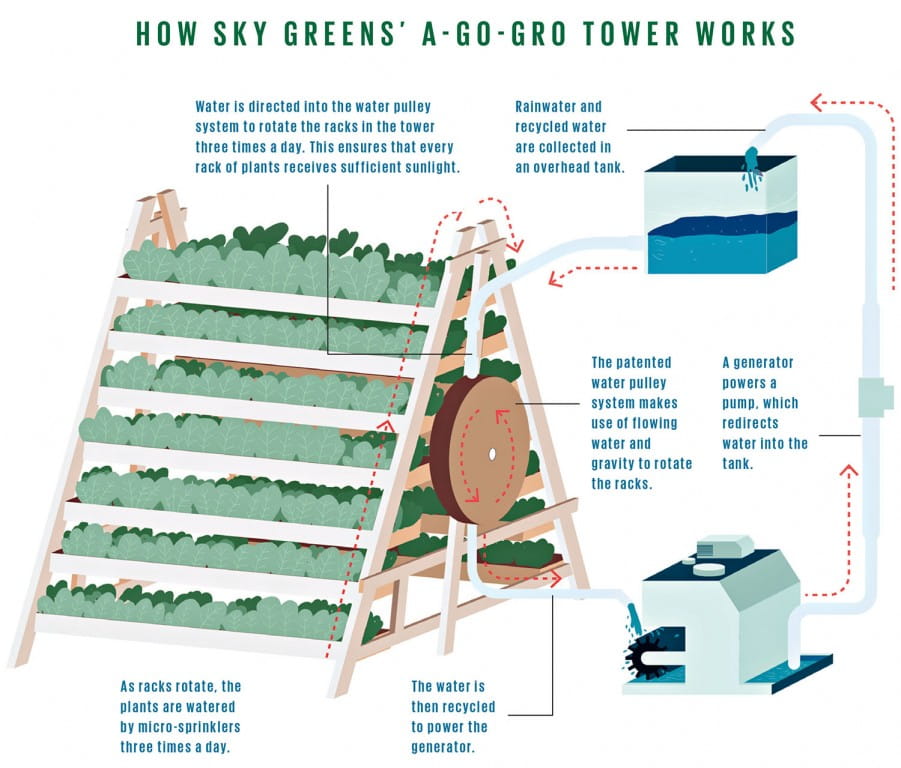

With support from the Agri-Food & Veterinary Authority of Singapore, the national authority responsible for food safety and the protection of the health of people, animals, fish and plants, Ng developed a multi-layer rotating A-frame vertical farming structure based on green technology.

He called it A-Go-Gro, which he patented in 2010. Each A-Go-Gro tower, which can reach up to a height of 9m, takes up about 5.5 sq m of space.

It takes about 40wh to power each tower, equivalent to powering a small light bulb. To produce 1kg of vegetables, it uses 5 cents of electricity and 12 litres of water.

Depending on the crop variety, each tower can produce 50kg to more than 100kg of greens for every growing cycle, or up to one tonne per year. That translates to an annual yield of up to 800 tonnes per hectare.

Currently, there are 800 such towers on its 3.65ha farm – about the size of five football fields – which has the capacity to hold up to 2,000 towers.

When fully built, the farm’s total investment on the land, infrastructure and support buildings would come up to S$26 million.

Its produce is sold at NTUC FairPrice supermarkets in Singapore. For the moment, only four types of leafy Asian vegetables – mustard greens, milk cabbage, bak choy and Chinese endive – are grown commercially on the farm.

However, it has also successfully cultivated cherry tomatoes, cucumbers, strawberries, rice and other types of greens. It is looking into introducing more varieties soon, but that will depend on economic considerations as well as growing expertise.

Sky Greens prides itself on using minimal land, water, energy and labour resources to grow vegetables compared to conventional farming methods. On a similar-sized plot, its technology can produce more than 10 times the yield of traditional open field farming. The structures do not even have to be sited on arable land, and can be built over reservoirs and rivers, and within urban locations, thus maximising land use while reducing logistics costs and carbon footprint.

However, the initial capital investment required to set up such a farm may be a barrier to entry for individual farmers unless they have financing options. Each unit is priced at S$6,500, S$10,000 and S$15,000 for the 3-m, 6-m and 9-m tower respectively.

The amount includes the cost material for the structure, such as the aluminium tower frame and the hydraulic system, but excludes other costs like on-site installation, custom duties and freight charges.

Nonetheless, the company will continue tapping the potential of urban farming to help cities feed their populations and improve the social and economic prospects of the agricultural industry.