Metropolitan Fishery Group measures the oxygen level in the water to ensure the optimum level is maintained for maximum yields of healthy fish for consumption.

Fish farmers are employing technology to increase Singapore’s fish production to meet increasing local demand and to stay self-sufficient. In June 2015, Singapore’s first vertical fish farm will be launched, in collaboration with a Dutch consulting company.

By Joyce Huang

“Give a man a fish and he eats for a day. Teach a man to fish and he has to first buy a fishing rod, hook and bait, then a fishing hat, glasses and clothes, then a boat and a club membership and finally when he cannot catch anything, he builds a fish farm so he has fish to eat for a lifetime!” says Malcom Ong, owner of Metropolitan Fishery Group.

The Group is currently one of Singapore’s largest fish farming groups with three farms off the coast of Lim Chu Kang and a fourth at Singapore’s eastern coast, Changi. The farms jointly breed milkfish, mullet, tilapia, trevally, pompano and red and gold snappers for local and overseas consumption.

Ong, a former managing director of an IT firm, set up the fish farm with fishing veterans Lim Sin Guan and Tay Yong Peng, the group’s two other shareholders. Ong handles the legal, administrative and technical aspects of the business while Lim and Tay lend their expertise on conventional fish farming.

SMARTPHONE MONITORING

Metropolitan’s fish farms run on sustainable systems, such as solar panels to tap into renewable energy.

In addition to this, Metropolitan has also been relying on a sustainable high-tech water-monitoring system to maintain the right levels of oxygen in its water. When the oxygen level in the water is low, an alert is sent so that staff can activate an oxygen pump to aerate the water. This information is also relayed to Ong’s smartphone to allow him to access the water monitoring system remotely.

The use of such technology helps the fish farm to achieve an annual production of about 800 tonnes. Says Ong, “We are pushing really hard to increase that to 1,000 tonnes. Optimistically, I think we’ll be able to hit the target next year.”

Metropolitan fish farms are run on sustainable systems, such as solar panels to tap into renewable energy.

RECYCLED FISH FEED

Metropolitan is also currently part of a project that uses recycled food waste as part of a lower-cost and more sustainable alternative fish feed. The project turns soy manufacturing by-products and fish processing trimmings into economical, nutritious and safe fish feed and is co-funded by Agri-Food and Veterinary Authority (AVA) and Spring Singapore, and involves research inputs from Ngee Ann Polytechnic’s Environmental and Water Technology Centre of Innovation.

Malcolm Ong, Owner of Metropolitan Fishery Group holds up a tilapia which has been tagged with a QR code, which provides data such as its origins and even recipes. His farm uses a water-monitoring system that can be accessed remotely from a smartphone.

Ong says: “We are conducting more trials that hope this will result in the same amount of nutrition provided fish at lower cost.”

Another initiative Metropolitan is looking to implement is vertical fish farming that is found in the Netherlands, where Ong observed fish cages being stacked on top of each other in the breeding process. By June 2015, Singapore will see the nation’s first vertical fish farm, the result of a collaboration with a Dutch consulting company.

Solar panels are used to generate power for the farms’ pumps, motors and even freezers containing ice to store harvested fish.

MEETING LOCAL DEMANDS

The Agri-Food and Veterinary Authority (AVA) has a $20 million fund to help diversify Singapore’s food supply and develop farms’ capabilities by looking at implementing more productive and sustainable fish farming methods based on technology and automation. For example, it has installed an online water quality monitoring system at several fish farms — AVA calls and text-messages fish farmers to alert them of poor water conditions so that they can mitigate the issues.

By 2015, AVA hopes to see locally harvested fish, supplied by 119 licensed coastal fish farms located around the island’s waters, rise from 7% to 15% of the average consumption of 100,000 tonnes a year.

Hydro-Pure’s water filtration system effectively detoxifies and purifies the water to ensure a safe and stable environment for the fish.

MAKING A SPLASH

The ornamental fish scene in Singapore is flourishing.

Ornamental fish farm Qian Hu employs technology to develop a sustainable farming system suited to Singapore’s environment.

The aquatic farm located at Jalan Lekar in the eastern part of Singapore, has put the Republic in the forefront as the world’s single largest exporter of ornamental fish — this refers to brackish or fresh water fish, crustaceans and coral bred in aquariums as a hobby and excludes consumable fish.

Last year, Qian Hu exported four million ornamental fish, or about 5-6% of the world’s total supply to 80 countries with USA, UK, Germany, China and Japan being its top markets. It started out as a guppy breeder in 1985 and today, the farm contributes about 15% of Singapore’s ornamental fish supply.

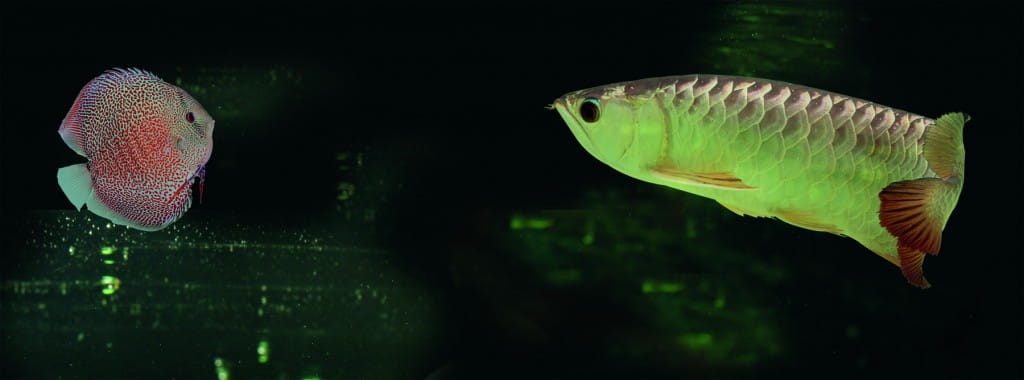

The farm has been harnessing technology to augment both its output as well as improve the quality of the ornamental fish — dragonfish (or arowana), discus and the South American suckerfish — that it exports.

ECO-FRIENDLY, ENERGY-EFFICIENT

For a company to remain sustainable, Kenny Yap, Qian Hu’s Chairman and Managing Director, says: “Innovation is the only way. We employ technology because it will ultimately lead to running a more productive and efficient farm. It’s about finding a new way of doing the same thing.”

One such technological advancement that was developed by the company’s dedicated research and development team is the energy-efficient Hydro-Pure filtration system, which offers energy savings of between 30% and 50%; and also promotes a natural, chemical-free environment for aquatic farming.

“Hydro-Pure enhances the cleaning process of aquarium water, removing up to 50% of toxic waste produced by the fish as compared to conventional filtration methods. This helps the fish stay healthier and survive longer while requiring less water,” says Alex Chang, who heads the group’s integrated research and development department.

In 1998, when Yap took over the helm from his father and uncle, the company’s founders, he diversified the business by moving into wholesale distribution, and also started manufacturing and distributing aquarium accessories, fish food and medication to treat sick fish.

In 2012, Qian Hu was conferred top honours (small and medium enterprises) at the Singapore Sustainability Awards by the Singapore Business Federation, for building a sustainable business environment.

Its business achievements aside — it is also an organisation with a heart — the company donates to various charities including the Geylang East Home for the Aged and organises farm visits for underprivileged and handicapped children from various welfare organisations.

To chart Qian Hu’s journey from a family business to worldexporter stature, in 2004, Yap wrote a book called What the Fish! The Makings of an Asian Entrepreneur, where he talks about his family, upbringing and the experience of running the fish farm.

With the aid of technology and a new generation of enterprising farmers like Yap and Ong, it looks like Singapore’s fish farming industry is set to make a big splash.

By Swapna Mitter with additional reporting by Evonne Lyn Lee